Water Treatment Chemicals

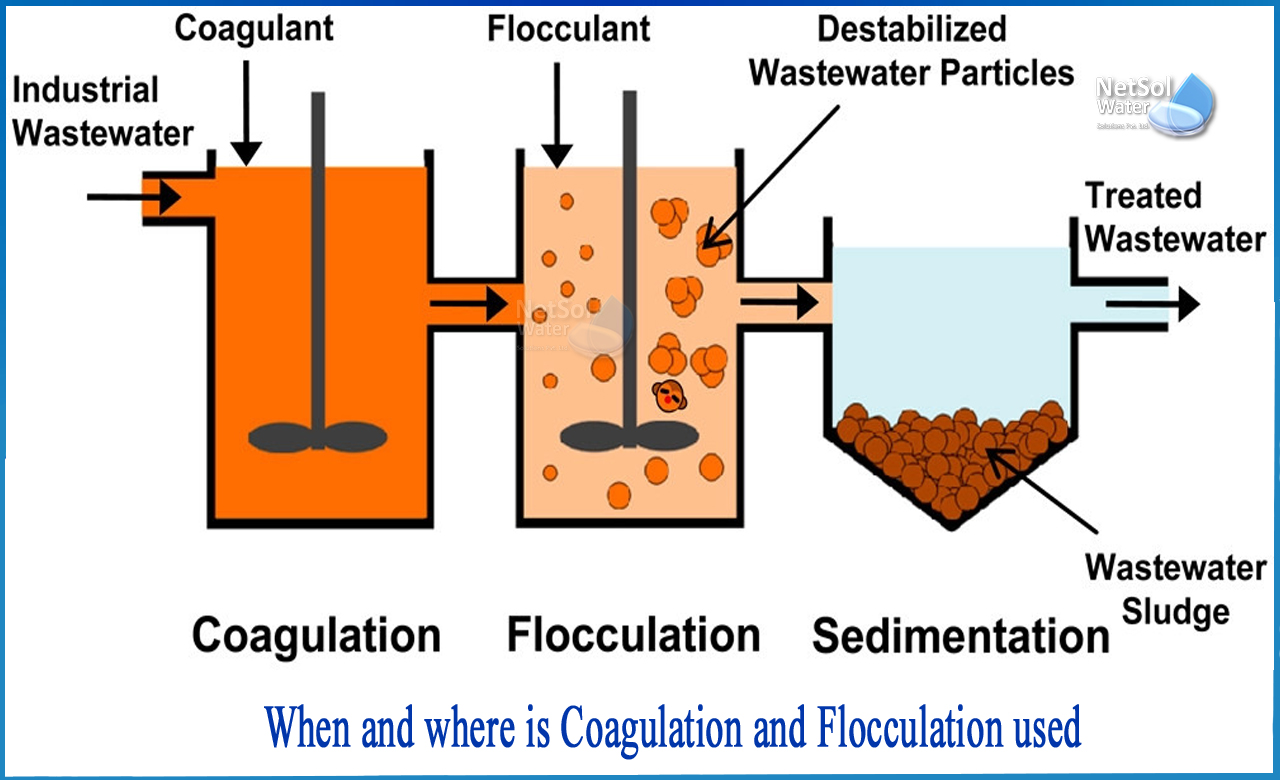

Coagulation and Flocculation

Coagulation and flocculation involve adding chemicals like alum or ferric chloride to destabilize particles in water, forming larger aggregates (flocs) that can be easily removed through sedimentation or filtration.

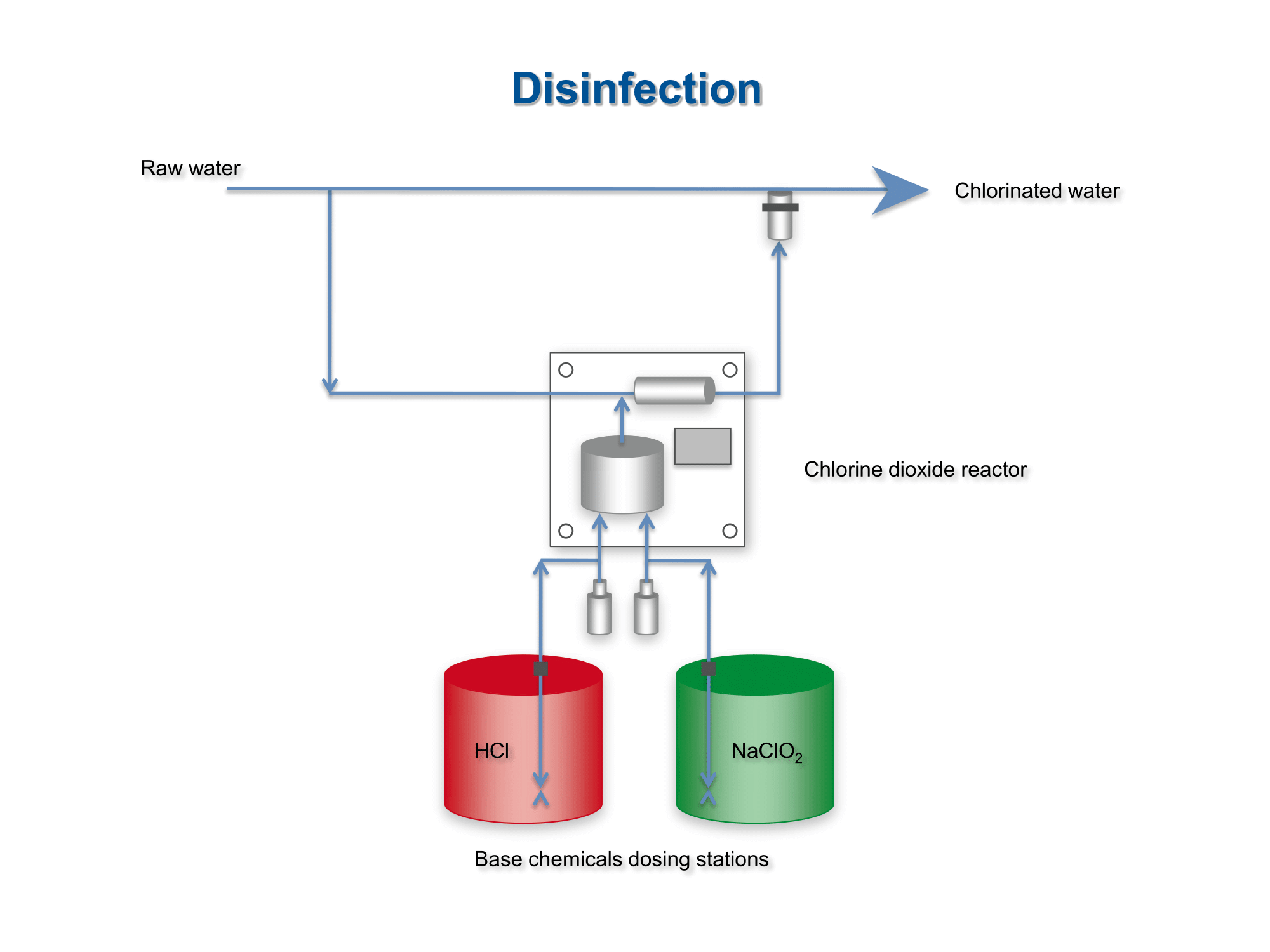

Disinfection

The disinfection process eliminates harmful microorganisms in water using chemicals like chlorine, ozone, or UV light, ensuring safe water for consumption, industrial use, and environmental discharge.

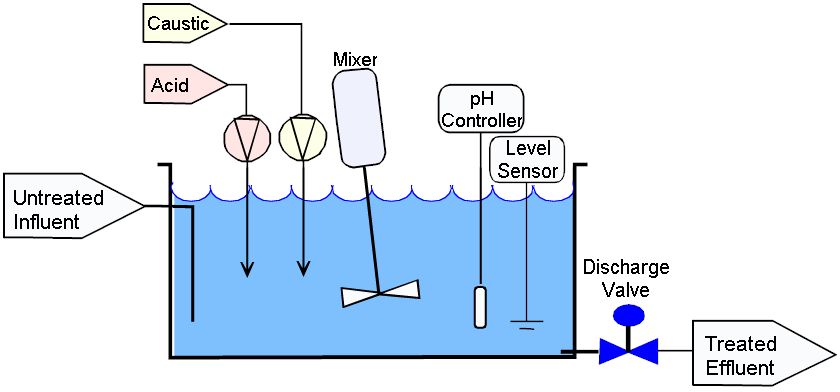

pH Adjustment

The pH adjustment process involves adding chemicals like lime, soda ash, or acids to regulate water pH, ensuring optimal levels for treatment efficiency, corrosion prevention, and compatibility with downstream processes.

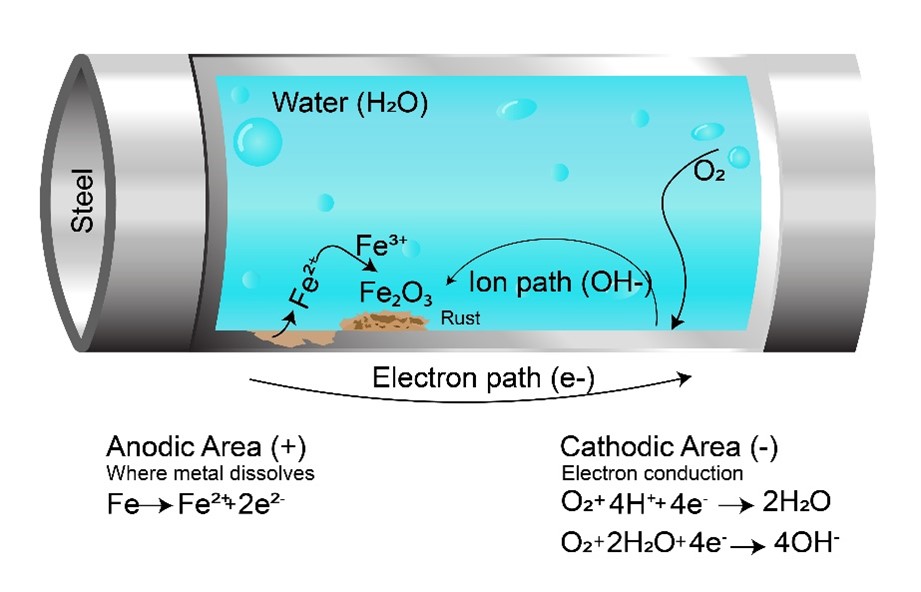

Scale and Corrosion Inhibitors

Scale and corrosion inhibitors prevent mineral deposits and metal degradation in water systems by using chemicals like polyphosphates and silicates, forming protective layers and ensuring efficient, long-lasting equipment performance.

Oxidation

Oxidation inhibitors prevent the chemical reaction between oxygen and metals in water systems, reducing rust and corrosion. These chemicals form protective films, enhancing equipment lifespan and ensuring water quality stability.

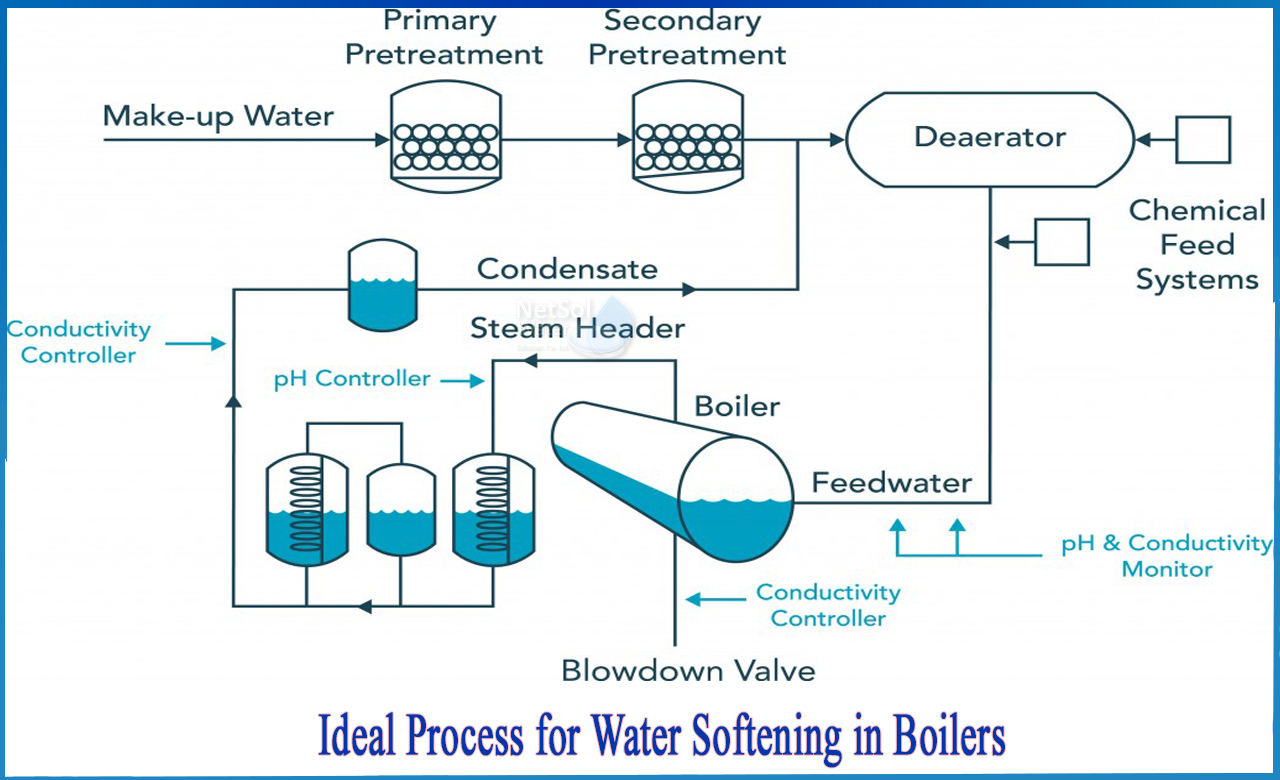

Softening

The softening inhibitors process uses chemicals like sodium chloride or phosphates to prevent mineral deposits (scaling) and reduce water hardness by neutralizing calcium and magnesium ions, enhancing system efficiency.